Hot and Cold Integrated Oil Mold

Send Inquiry

Why Choose Hot and Cold Integrated Oil Mold?

What ensures stable performance? USA-imported Copeland compressor + OMRON/FUJI/TE/LG electrical parts for longer service life.

How to avoid blockage and rust? Oxygen-free copper pipe welding + 304 stainless steel integrated pipelines.

Can it save energy? High-efficiency evaporator and condenser, reducing energy consumption by over 30%.

Is operation flexible? 3 compressors (8ACH model with 2 groups of heads for separate/joint use) + heating power switchover.

Supports automated management? Optional RS485 communication + imported microcomputer/PLC control (optional).

Easy to maintain? Perfect safety protection, fault display, and hassle-free repair without professional skills.

Product Overview

AQWK focuses on providing high-quality Hot and Cold Integrated Oil Mold. The products have passed the dual international certifications of CE and RoHS. They comply with international norms in terms of safety standards and environmental protection requirements. With dual guarantees of quality and compliance, they can be safely applied in various industrial production scenarios.

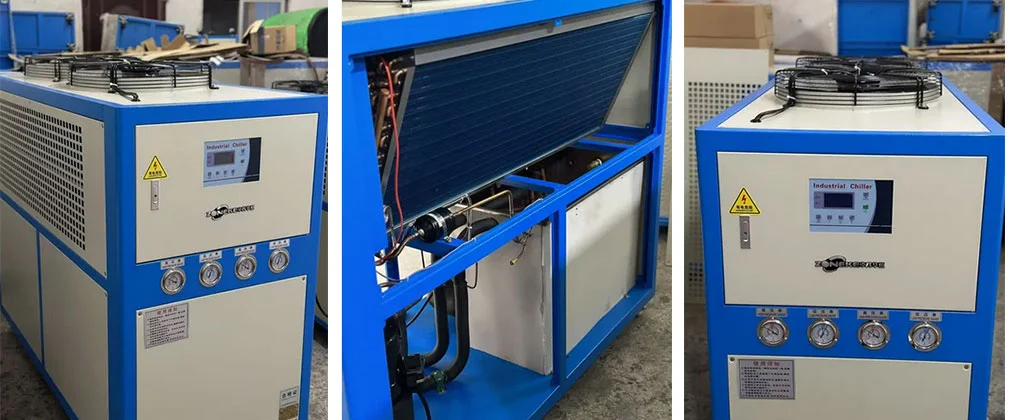

As a professional device integrating hot and cold functions, this oil temperature control machine performs outstandingly in core performance parameters. The adaptability range of the inlet water temperature covers 5℃ to 98℃, which can precisely match the differentiated requirements of different production processes for inlet water temperature. Whether it is low-temperature cooling or medium and high-temperature temperature control scenarios, it can stably output. With a cooling capacity of 12.5kw, it can quickly achieve heat exchange, efficiently regulate the oil temperature, ensure a constant temperature during the production process, and help improve the forming accuracy of products and production efficiency.

The Hot and Cold Integrated Oil Mold is compatible with the standard industrial voltage of 380V/50HZ. It does not require additional modifications to the existing power supply system of the factory and can be directly connected to the production line, greatly simplifying the installation process and reducing the deployment cost. In addition, this equipment adopts an air-cooled design, achieving an ultra-quiet operation during the process. It can effectively reduce noise pollution in the industrial production environment, creating a more comfortable working atmosphere for workshop operators, and balancing the practicality of the equipment and the user experience.

Product Specifications

| Model: | AQ-5ACHS-12L*3 |

| Type: | Air-Cooled |

| Cooling Method: | Water-Cooled |

| Unit Structure: | Integral |

| Voltage: | 380V/50HZ |

| Compressor Number: | 3 (Copeland, USA Imported) |

| Noise Level: | Ultra Quiet |

| Temperature Range: | 5°C-98°C (incoming water), -30°C to +350°C (working condition) |

| Cooling Capacity: | 12.5kw |

| Application Fields: | Electroplating, Brewery, Beverage Factory, Food Industry, High Ambient Temperature Countries |

| Application Machine: | Precision Machine Tools |

| Certification: | CE, RoHS |

| Condition: | New |

| Delivery Time: | 15-20 Days |

| Warranty: | 2 Years |

| After-Sales Service: | Overseas Machine Service |

| Trademark: | AQWK |

| Transport Package: | Wooden Case |

| Specification: | 120kg |

| Origin: | China |

| HS Code: | 8419899090 |

Factory Promotion & Application Value

Ideal for industries requiring low temperature control (brewery, beverage, food, etc.) and high ambient temperature regions. With years of manufacturing experience, we offer factory-direct promotion prices, reliable quality backed by top-tier components, and global after-sales support. The unique design of Hot and Cold Integrated Oil Mold adapts to extreme working conditions, meeting diverse production needs.

If you have any questions, please contact us:

Mobile/WeChat: +86-13336655820

Email: sales9188@foxmail.com

-

E-mail